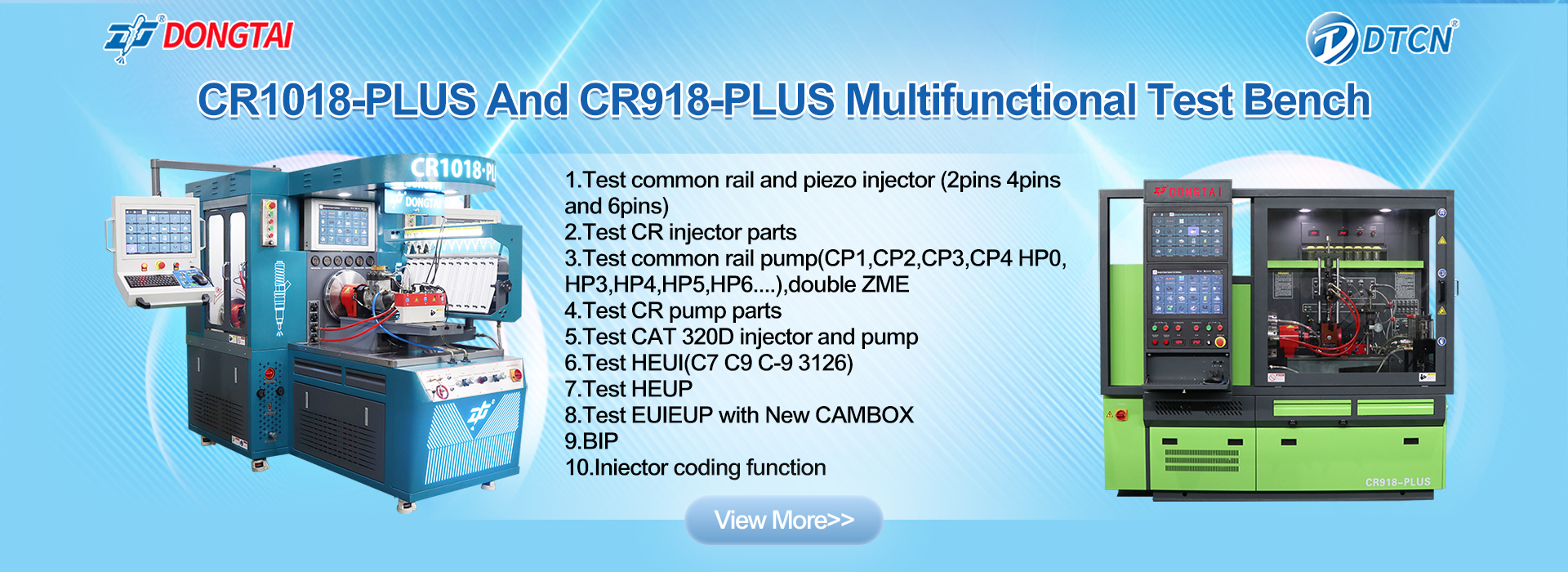

- Test Bench

Diesel Injection Pump Test Bench Common Rail Injector Test Bench Common Rail Injector and Pump Test Bench EUI EUP,HEUI,CAT320D TEST BENCH Common Rail Simulator Nozzle Tester EDC Pump Tester/Sensor Tester CRI Stroke Measuring System PT Cummins Test Bench Balance Machine Work Bench Fuel System Tester DIAGNOSTIC SCANNER Stage3 Common Rail Injector Measuring Tools DPF,DOC,SCR Cleaning Machine

- Common Rail and EUI EUP HEUI HEUP Tools

- Diesel Engine Parts

Spare Parts Nozzle Plunger Head Rotor Delievery Valve Common Rail Shims Diesel Injector Tight Hat List 12V, 24V Solenoid Valve Bosch Pump Diesel Regulating Valve DRV Bosch Fuel Metering Valve DRV Bosch Fuel Rail Pressure Sensor Bosch Injector Valve Assembly Bosch Injector Valve Cap Pressure Limiting Valve Denso Valve Denso Valve Rod Denso SCV Valve Delphi Valve Delphi Rail Pressure Sensor Delphi Inlet Metering Valve CAT Plunger CAT Plunger Pump CAT Delievery Valve

- Bosch

- Denso

- Delphi

- CAT

- Cummins

- Siemens VDO

- Ultrasonic Tank Cleaner

- Wheel Loader

- Air Compressor

- AC Refrigerant Recovery Machin

PRODUCTS products

-

Free hotline

0086-13455388360

BD860 Diesel Injection Pump Test Bench

Content

Introduction

BD860 adopt industrial pc with color CRT, It’s the newly researched production for the direction of high power and safety to the environment. It has human-machine interface, digital controlling of rpm, temperature, pressure, diesel fuel pump technical parameter and so on, and in pace with print. It easy and quick operates ,it’s really human-machine dialog. This series test bench adopt high quality frequency conversing device and cast iron base supper size bed, and its distinguishing features are hi-stable character, hi-reliability, ultra-low-noise, perfect auto-protecting function and so on, It is advanced products.

Main function

1.Measurement of each cylinder delivery at any speed。

2. Test point and interval angle of oil supply of injection pump.

3. Checking and adjust the mechanical governor.

4. Checking and adjusting the distributor pump.

5.Experiment and adjusting of behavior of supercharging and compensatory device.

6. Measurement of oil return of distributing pump

7. Testing of the electromagnetic valve of distributor pump.(12V/24V)

8. Measurement of the internal pressure of distributor pump.

9. Checking of the advance angle of advance device.(on request)

10. Checking the sealing of injection pump body

11. Install tube of auto-sucking oil supply can check on oil supply pump(including VE pump.)

12. Checking the travel of stroke

13. Oil lubricate(on request)

14.Cast iron base(on request)

15. Foced cooller(on request)

16. Two operating systems(Computer control + Digital control)

17. LCD touch screen (on request)

|

Adjustable cylinders numbers |

Out power(Kw) |

RPM |

Rpm pre-set |

Temperature control system |

Positive pressure system |

Positive pressure system |

|

12 |

7.5 |

0-4000 |

√ |

√ |

√ |

√ |

|

11 |

||||||

|

15 |

||||||

|

18.5 |

||||||

|

Air supply |

DC power supply |

internal pressure of VE pump |

Oil return of VE pump |

travel of tooth bar |

Advanced angle |

Capability with pump type |

Add: High-Tech Zone, Taian, Shandong, China.

TEL:+86-13455388360 FAX: +86-538-2096189 E-mail: [email protected]

TAIAN DONGTAI MACHINE MANUFACTURING CO.,LTD 備案號:魯ICP備15006010號-1