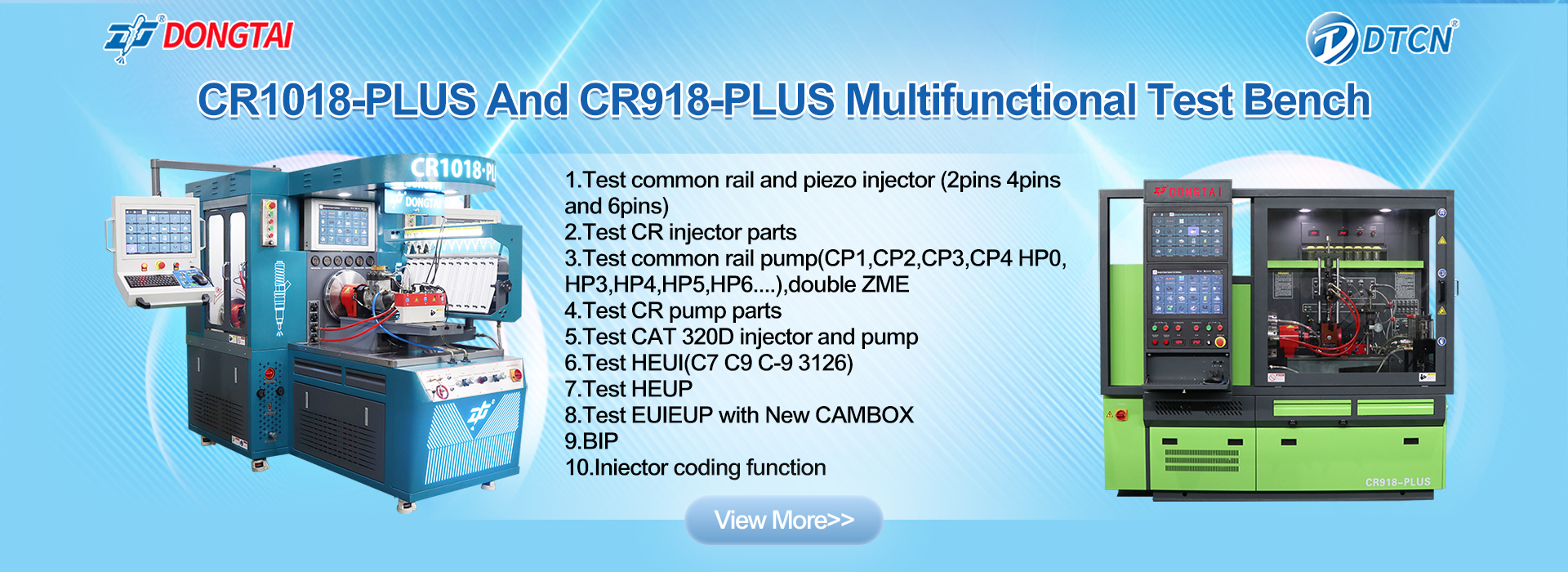

- Test Bench

Diesel Injection Pump Test Bench Common Rail Injector Test Bench Common Rail Injector and Pump Test Bench EUI EUP,HEUI,CAT320D TEST BENCH Common Rail Simulator Nozzle Tester EDC Pump Tester/Sensor Tester CRI Stroke Measuring System PT Cummins Test Bench Balance Machine Work Bench Fuel System Tester DIAGNOSTIC SCANNER Stage3 Common Rail Injector Measuring Tools DPF,DOC,SCR Cleaning Machine

- Common Rail and EUI EUP HEUI HEUP Tools

- Diesel Engine Parts

Spare Parts Nozzle Plunger Head Rotor Delievery Valve Common Rail Shims Diesel Injector Tight Hat List 12V, 24V Solenoid Valve Bosch Pump Diesel Regulating Valve DRV Bosch Fuel Metering Valve DRV Bosch Fuel Rail Pressure Sensor Bosch Injector Valve Assembly Bosch Injector Valve Cap Pressure Limiting Valve Denso Valve Denso Valve Rod Denso SCV Valve Delphi Valve Delphi Rail Pressure Sensor Delphi Inlet Metering Valve CAT Plunger CAT Plunger Pump CAT Delievery Valve

- Bosch

- Denso

- Delphi

- CAT

- Cummins

- Siemens VDO

- Ultrasonic Tank Cleaner

- Wheel Loader

- Air Compressor

- AC Refrigerant Recovery Machin

PRODUCTS products

-

Free hotline

0086-13455388360

DTS619-I Diesel Injection Pump Test Bench

Content

Technical parameter:

1. Adjustable rotation speed range: 0~4000rpm

2. Double series of graduates: 45/150CC

3. Volume of oil tank: 100L

4. Temperature stabilization: 40±2℃

5. Test oil filtering unit: 5μ

6. DC. Supply: 12/24V

7. Feed pressure: 0~0.4MPa (low), 0~4MPa (high)

8. Air pressure (MPa): -0.03~0.3

9. Rack travel range: 0~25mm

10. 3-phase power supply: 380V/50Hz or on request

11. Flywheel inertia’s moment: 0.8kg·m2

12. Center height: 125mm

13. Output power: 7.5kw~15kw

14. Overall dimensions: 200X90*170CM

15. Net weight (kg): 1000.

16. Average trouble-tree working time of test stand: ≥2500h.

Functions:

1. Test and debugging about oil supply amount and uniformity each cylinder of injection pump.

2. Check the oil supply spacing of each cylinder and oil supply starting point in the static state.

3. Check and adjust the performance of mechanical speed controller.

4. The sealing inspection of pump body.

5. The test of solenoid valve of distribution pump.

6. The test of return oil of distribution pump.

7. Measure the interior pressure of distribution pump.

8. Check the vacuum capacity regulators.

9. Check the pressure of compensator.

10. Check the fuel supply pump.

11. Measure the advance timer device.

12. User can change the temperature.

Characteristics:

1. Advanced frequency conversion technology and industrialized computer control technology, with rotation speed, temperature, count numeral control, Industrial LCD double control display system.

2. English and Chinese menu.

3. Two sides operation manually.

4. Equipped with the relevant attachments for measuring the domestic and international various kinds of high pressure oil pumps

5. Measure the Rack Bar journey exactly.

6. Debug speed curve of injecting oil pump.

7. Automatic oil unloading device

8. Print and keep debugging data of pump.

9. Large inertia flywheel--- steady drive and good balance.

Add: High-Tech Zone, Taian, Shandong, China.

TEL:+86-13455388360 FAX: +86-538-2096189 E-mail: [email protected]

TAIAN DONGTAI MACHINE MANUFACTURING CO.,LTD 備案號:魯ICP備15006010號-1